What is industry if not the perfect application of human genius? We deeply believe in the pillars of Industry 5.0, where high-tech production is carried out preserving resources, empowering environment and society. Our company aims to develop the uniqueness of people and their creative potential, putting their wellbeing as part of our core business.

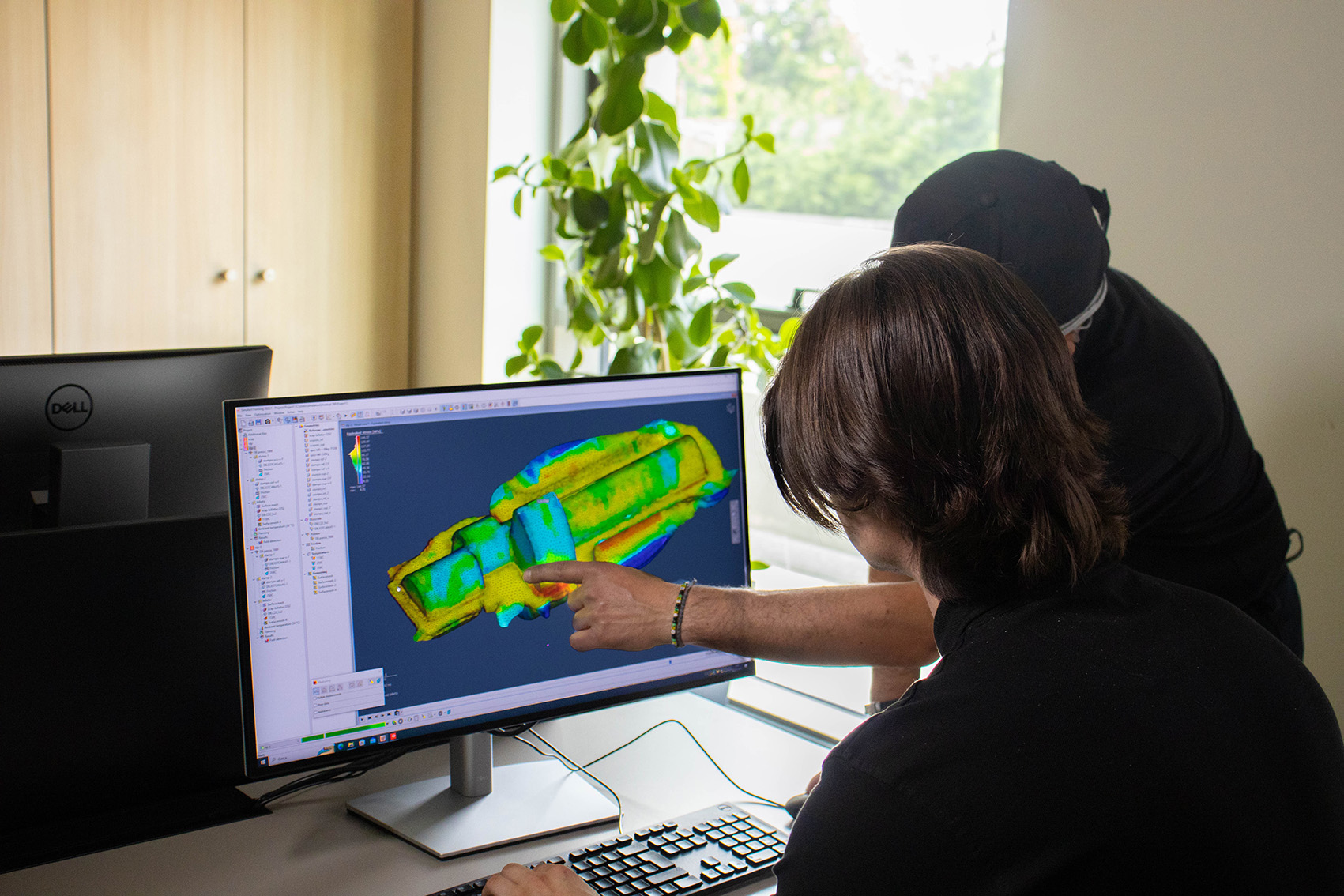

Our design and development department work out processes in partnership with our customers, through co-engineering activities and dedicated workshops. We perform FEM analysis for process tuning and for verification and calculation of product behavior. We program CNC machines and build our tools and dies totally in house: this is part of a strategically interconnected process where R&D, engineering department and tool manufacturing are all linked to optimize timing.

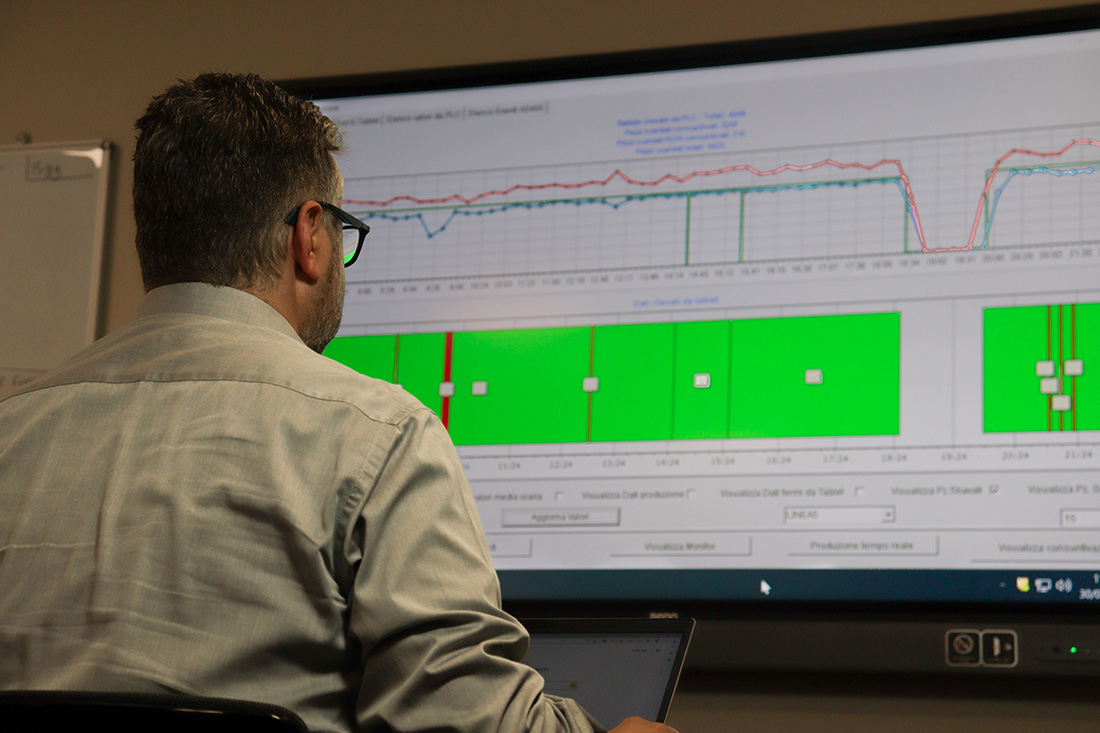

Our forging lines can produce components in a range from 1 to 30kg. Our forging presses have rated power from 10MN to 35MN . Through our skills to produce versatile geometries, we can supply different markets including passenger cars, light vehicles and trucks, construction equipment, agriculture, industrial markets and robotics.

All machining operations as turning, milling and drilling are carried out by CNC machinery. We can also handle special requests and provide our customers with finished products. A complete control of the entire production cycle and quality is ensured by a fully automated robotic facility.